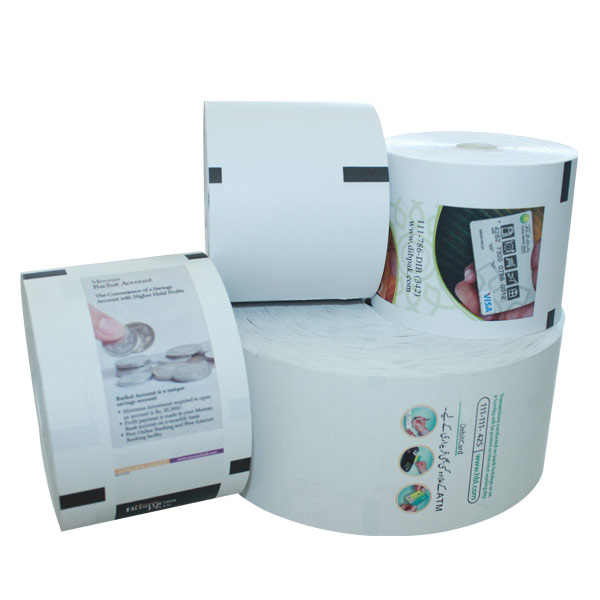

Thermal synthetic paper, also known as five proof thermal paper, is easy to preserve and save printing paper. Labels are not easy to be damaged in application, and their resistance to water and oil stains is also very high. Thermal paper is not so easy to solve these problems.

1、Thermosensitive synthetic paper

The surface of thermosensitive synthetic paper is a thick protective layer, and the bottom layer is a tear resistant adhesive sticker with strong ductility, which further improves its water, oil and abrasion resistance, and also has strong tear resistance and tensile properties. Thermal synthetic paper has the characteristics of abrasion resistance, tear resistance and moisture resistance.

The advantages of thermosensitive synthetic paper can be divided into the following seven points:

1. High quality thermosensitive synthetic paper with high tear resistance and tensile strength;

2. Water, oil and corrosion resistance;

3. Long storage time at room temperature and very slow fading;

4. The collagen fibers on the sticker surface are symmetrical and sticky;

5. The actual printing effect is clear and the color is mellow;

6. Be able to immediately write on the thermal synthetic paper with a pen;

7. It is very easy to store before application, and the printing paper is not easy to fade, which greatly reduces the consumption of printing costs.

2、 Thermal paper

Nickname of thermal paper: thermal fax paper, thermal recording paper, thermal printing paper, Taiwan called thermal carbon paper. Thermal paper is a kind of processed paper. Its manufacturing principle is to apply a layer of “thermal sensitive coating” (thermal color change layer) on high-quality base paper. The thermosensitive components of thermosensitive paper coatings are mainly two kinds: one is colorless or leuco dye, and the other is color developing agent. This type of thermal paper is also known as two group differentiation type thermal recording paper.

Application of thermal paper in label printing: thermal paper is divided into protective layer and non protective layer. The thermal layer is above the thermal layer, which is used to protect the thermal layer, resist chemical corrosion, prevent label pollution (such as sweat stains on hands, blood stains on labels used for blood banks, etc.) and protect the print head. The thermosensitive coating can be designed into different activation temperatures as required to meet the requirements of different printing performance.

Copyright © Suzhou Guanhua Paper Factory All rights reserved.