As we all know, first of all, we analyze the production of thermal paper, which is divided into three layers: base paper, coloring layer and protective layer. Among them, base paper is the base paper mentioned above, which can be understood as paper with better quality; The color layer is divided into three layers: the bottom layer, the thermal layer and the top layer.

The production process of thermal paper is first primer, then coating, and then top coating. The last step is calendering. The key is here. The colorless dye we use now mainly uses fluorescent substances. This is the powder. The calendering step reflects the technology. If we press it well, there will be no powder falling.

First, let’s talk about the key and easy to be ignored. Many heat sensitive papers, especially garbage paper without brands, add a lot of phosphor and calcium carbonate to improve the paper’s sense, which makes the paper drop a lot of paper scraps when printing and cutting, seriously affecting the life of the print head and automatic paper cutter.

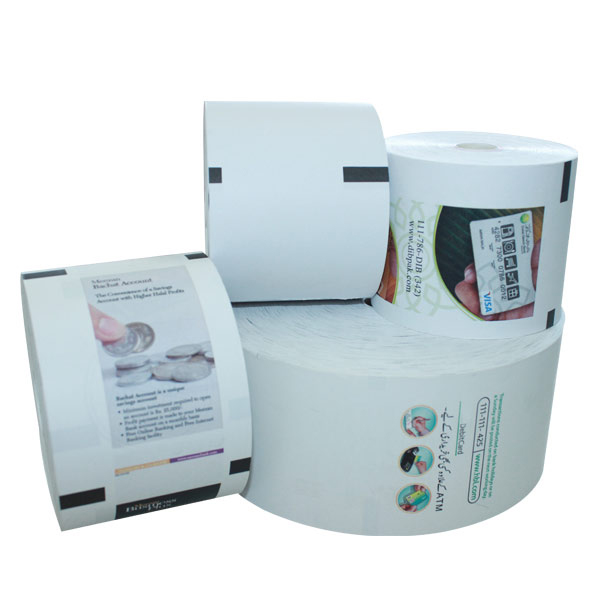

Thermal paper

1. Observation:

When shopping for thermal paper, pay more attention to the appearance of the paper. From the color, we can distinguish the quality of its protective coating and thermal coating. If the paper is very white, it means that the protective coating and thermal coating of the paper are unreasonable, and it is likely that too much phosphor is added. If the paper is slightly green, its quality should be better. If the paper looks smooth and flat, the coating of the thermal paper is more uniform; otherwise, the coating of the paper is uneven, which will seriously affect the printing effect. At the same time, if the paper seems to reflect strong light, it is also due to the addition of too much phosphor. It is recommended not to choose such thermal paper.

Thermal paper

2. Comparison and identification of sunlight exposure:

This method is very simple. Just smear different printed papers with the same fluorescent pen and put them in the sun (this can accelerate the reaction of the thermal coating to light). They will all turn black. The longer it takes to turn black, the longer the thermal paper will be stored.

Thermal paper

3. Fire baking:

In fact, the principle of fire baking is similar to that of sunlight. You can use a lighter to heat the back of the paper slowly, and the color of the paper will change with the heating. If the color is brown, it means that the heat sensitive formula is not reasonable, and the storage time may be relatively short; If there are fine stripes or scattered color patches on the paper, it indicates that the coating is uneven. On the contrary, the thermal paper with better quality will appear black green (with a little green) after heating, with even color patches, and the color will gradually fade from the center of heating to the surrounding.

Thermal paper

Thermal Paper manufacturer & supplier

Suzhou Guanwei Thermal Paper Co., Ltd. has introduced industrial equipment and talents, focused on the R & D, production and sales of thermal printing paper, and has a number of patents. It has successively developed products such as low wear thermal paper, long-term storage thermal paper (storage period up to 30 years), three proofing (oil, alcohol and friction resistant) thermal paper, and bisphenol A-free thermal paper. The performance of some products has been better than that of imported similar products. The company has a wide range of products, and the products it can provide to the terminal include thermal cash register paper, thermal tickets, movie tickets, printing customized thermal printing paper, medical record paper, ECG drawings, computer printing paper, self-adhesive labels, airline boarding passes, luggage tags and other products. We are best 7 thermal paper manufacturer. Please contact us.

Copyright © Suzhou Guanhua Paper Factory All rights reserved.