There is no obvious difference between carbonless copy paper and thermal paper in appearance, and can even produce the same effect, but why are the names of the two different? In fact, the color development principle of carbonless copy paper and thermal paper is completely different, and there are certain differences in the use of the two. Let me give you a detailed answer below.

Carbonless copy paper color development principle:

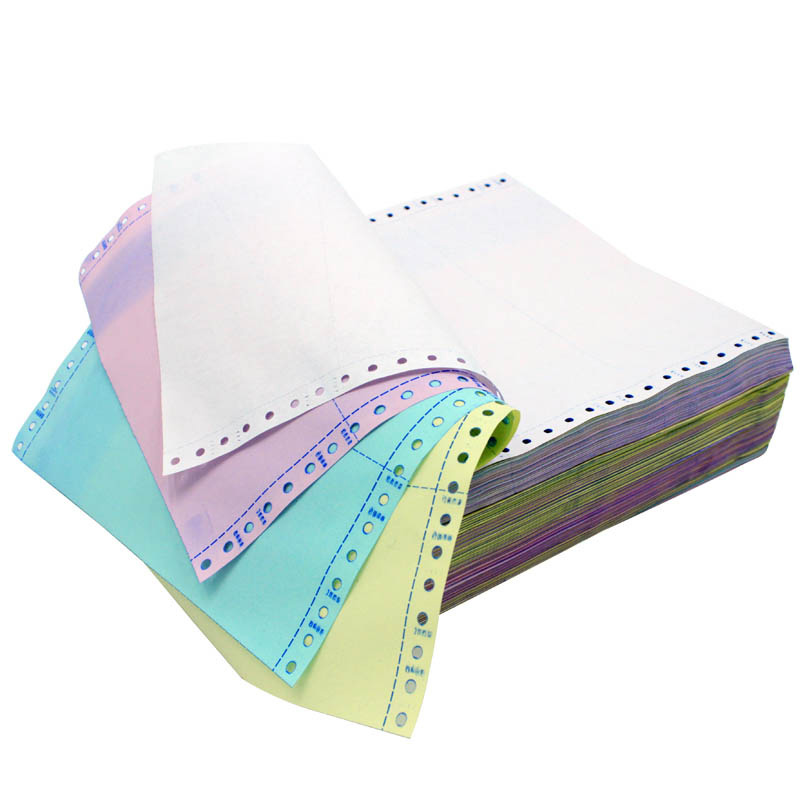

There are two types of coatings in carbonless copy paper: a CF layer containing a chromogenic agent and a CB layer containing a chromogenic agent. The chromogenic agent is a special colorless dye that has been dissolved in non-volatile carrier oil and encapsulated by microcapsules of 3-7 μm. The impact pressure of forceful writing and printing can crush the microcapsules, allowing the colorless dye solution to flow out and contact the color developer, and a chemical reaction occurs to present colored graphics, thereby achieving the purpose of copying. Carbonless copy paper is divided into 45g/m2CB paper, 47g/m2CF paper and 52g/m2CFB paper according to the quantity; according to the color of the paper, there are five kinds of red, yellow, green, blue, and white; according to the color traces, there are blue, Yellow, orange, black, red and other colors.

Thermal paper color development principle:

When the thermal paper is placed in an environment above 70°C, the thermal coating begins to change color. The reason for its discoloration also starts from its composition.

There are two main heat-sensitive components in the thermal paper coating: one is a leuco dye or leuco dye; the other is a color developer. This type of thermal paper is also called two-component chemical type thermal recording paper.

Commonly used as leuco dyes are: crystal violet lactone (CVL) of trityl phthalide system, fluorane system, colorless benzoyl methylene blue (BLMB) or spiropyran system and other substances.

Commonly used dispersants are: polyvinyl alcohol L-3266, polyvinyl alcohol GL-05, polyvinyl alcohol KL-03 (produced by Japan Synthetic Chemicals).

Commonly used top coat and bottom coat additives are: gohsefimer Z-200, polyvinyl alcohol T-350, polyvinyl alcohol N-300.

Commonly used as color reagents are: p-hydroxybenzoic acid and its esters (PHBB, PHB), salicylic acid, 2,4-dihydroxybenzoic acid or aromatic sulfone and other substances.

When the thermal paper is heated, the colorless dye and the developer undergo a chemical reaction to produce color, so when the thermal paper is used to receive a signal on a fax machine or print directly with a thermal printer, the graphics and text will be displayed. Since there are many kinds of leuco dyes, the colors of the handwriting that appear are different, such as blue, purple, black and so on.

Copyright © Suzhou Guanhua Paper Factory All rights reserved.