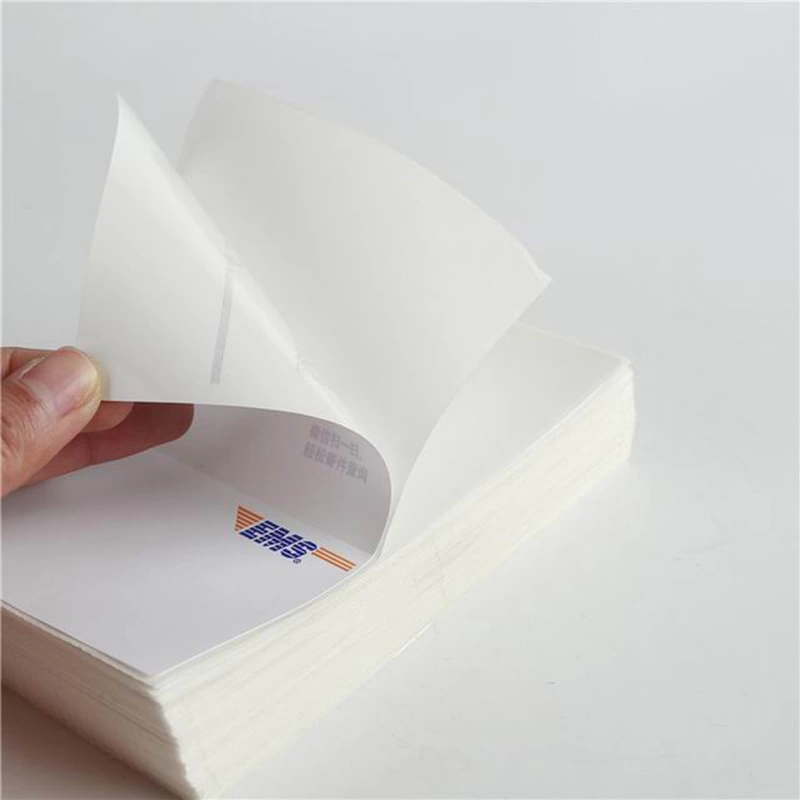

The reason why the self-adhesive label is widely used is that, compared with the traditional label, the self-adhesive label has the advantages that the traditional label does not have. Self-adhesive printing refers to the printed matter printed on a composite material with paper, film or other special materials as the fabric, adhesive coated on the back, and silicon-coated protective paper as the base paper: as far as the product form is concerned, it is Composite single-page prints, coated with adhesive on the back, can be glued to the place where the customer needs to be glued.

Self-adhesive printing In terms of printing methods, self-adhesive printing usually uses screen printing. In recent years, due to the development of offset printing technology, self-adhesive printing also uses offset printing. Films and printing plates must be produced before printing. As far as post-press processing technology is concerned. Self-adhesive label paper, also called self-adhesive label paper, is mainly used in liquid washing products and popular personal care products; film materials are mainly used in daily chemical products in China. Personal care products and household liquid washing products that are popular on the market account for a large proportion, so the corresponding paper materials are used more.

Compared with traditional labels, the self-adhesive label does not require gluing, no sticking, no need to be immersed in water, no pollution, saving label time, and easy and fast to stick on various occasions. Various types of labels with different fabrics, adhesives and backing papers can be applied to materials that cannot be used with ordinary paper labels. It can be said that self-adhesive is a kind of label.

The printing of self-adhesive labels is very different from traditional printing. Self-adhesive labels are usually printed and processed on the label link, and multiple processes are completed at one time, such as graphic printing, die cutting, waste discharge, cutting or copying. Self-adhesive printing refers to a composite material that uses paper, film or other special materials as fabric, coated with adhesive on the back, and silicon-coated protective paper as the base paper. It is a printed matter printed in the form of a product. It is a composite The single-page printed matter is coated with adhesive on the back, which can be glued to the place where it needs to be glued.

Self-adhesive printing In terms of printing methods, self-adhesive printing usually uses screen printing. In recent years, due to the development of offset printing technology, self-adhesive printing also uses offset printing. Films and printing plates must be produced before printing. As far as post-press processing technology is concerned. That is, one end is the raw material input of the entire roll, and the other end is the output of the finished product. The finished product is divided into single label or roll label, and the finished label can be directly attached to the product. Therefore, the self-adhesive label printing process is more complicated, and the requirements for equipment performance and the quality of printing personnel are also higher.

Copyright © Suzhou Guanhua Paper Factory All rights reserved.